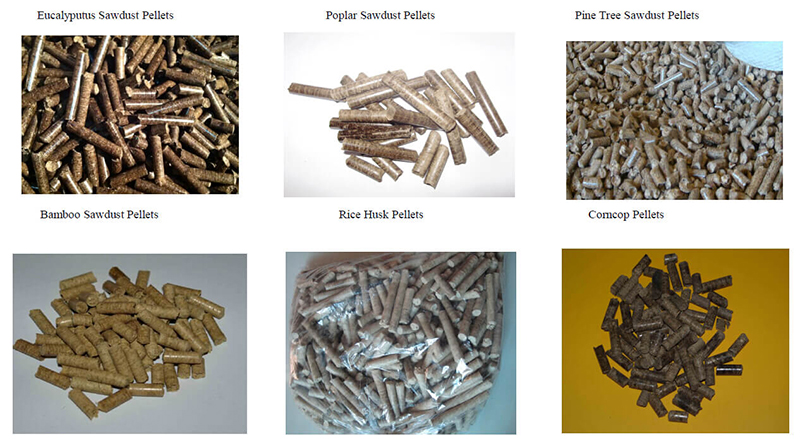

The wood pellet machine is to make the crushed material of wood chips, branches, straw, grass, rice husks, etc. into granular fuel products. Because different industries have different requirements for fuel density. Therefore, after extrusion processing with wood pellet machine, the fuel value contained in different raw materials is different. Corn stalks processed with straw pellet machine and the combustion value is about 3800 kcal. The fuel combustion value of rice husks and peanut husks is slightly higher, but there will be differences according to different regions.

Production Advantages Of Wood Pellet Machine For Biomass Industry

1. Higher production efficiency, increase industry capacity.

The industry buys wood pellet machines mainly for the processing of raw materials and auxiliary production of commodities. The production efficiency of the wood pellet machine is high. Biomass pellets produced per unit hour can provide the industry’s daily production capacity.

If the industry completes production only by purchasing wood during the production process, once the supplier becomes out of stock, the industry’s production line will have to stop. In industries with more constraints, buy a wood pellet machine and control the supply of raw materials in yourself. The high output of equipment will continuously accelerate the production of the industry and will not bring any restrictions to the industry.

2. The lower-cost investment of equipment produces greater economic benefits。

The price of wood pellet machine is small, the energy consumption of equipment is small, the industry’s overall investment cost in equipment is less. Compared with the economic benefits, the investment cost can be said to be very small.

The raw materials for the production of wood pellet machine can be waste wood, value, old home, etc. As long as it is wooden products, no matter old or new, it can be used as raw materials to produce high-quality wood pellets, without any impact on the quality of industrial production. Therefore, the wood pellet machine is production equipment that must be equipped in the production of the wood industry. The economic benefits of equipment should be recognized by all walks of life.

The wood pellet production line equipment turns wooden products into energy resources without changing any performance. It only gathers their dispersed energy for use in our lives and our economic development.